Improve Lifespan of PTFE Teflon Tabber Stringer Belt

Update time: 2024-09-24 Views: 900

Description

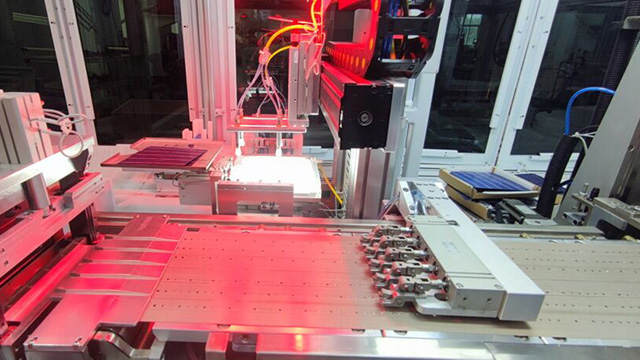

With the continuous development of building integrated photovoltaics (BIPV), more and more photovoltaic modules are applied to daily life and industrial production. Among them, welding is an important process in the photovoltaic module process. Cells and welding strips are placed on the conveyor belt by the welding machine, and then transported to the welding station by the welding belt. The welding station performs the welding operation according to the preset process parameters to realize the automatic welding of the photovoltaic cell sheet and the welding strips, and the photovoltaic cell sheets are connected in series in such a circular transmission. The welded solar cell strings become photovoltaic modules used in the construction of photovoltaic power plants after series-parallel connection, frame packaging and other processes.

However, due to the long-term work of the stringer, there will be a lot of debris, residue, dust and other residues in the stinger belt, so it is easy to cause hidden cracks, fragments, scratches and other problems in the stringer belt. On the one hand, the tabber stringer belt will be corroded and bulged by the flux, which will cause the stinger belt offset and inveracious soldering, which will affect the quality of the finished product of the photovoltaic module.

To sum up, the quality and the maintenance of the belt plays particularly important role in the production of photovoltaic modules. Thus we need to improve photovoltaic module production efficiency from these two aspects.

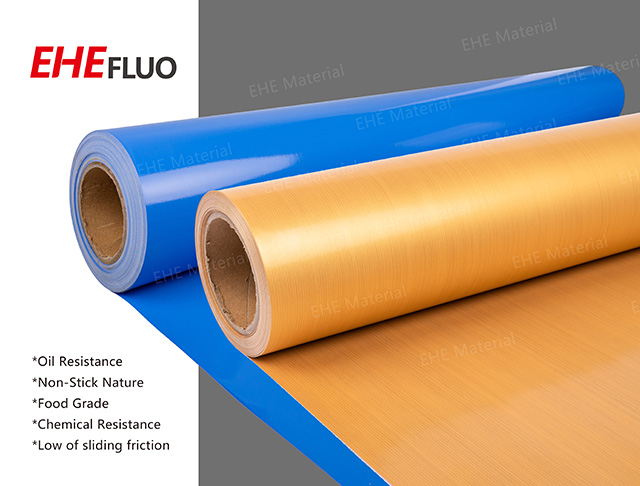

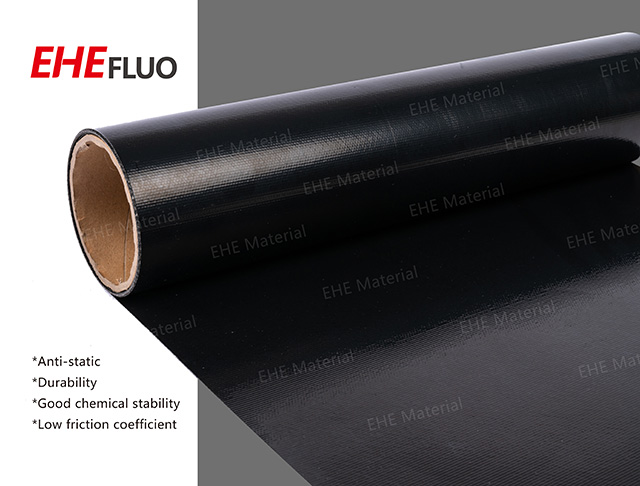

Firstly, we need to improve quality of the conveyor belt which is called “stringer belt” here, the belt transport solar panels which are held in place via vacuum holes along the belt. We make the belts by laminating two layers of PTFE glass cloth together, we can create a belt that has even thickness through, that means the joint thickness is the same as the rest of the belt. Actually laminating process is very common in our industry, but belt from Scifluo is not made by this normal laminating process. We improve the quality from two aspects: Material and Machine. From the material aspect, the belt is running at high speed, and the solar cell pieces will be continuously placed on the belt, which requires the belt with strong substrate and wear-resistant surface, Scifluo improve the strength of PTFE coated glass cloth material from the basic substrate because the belt will run in high speed, and modified the PTFE coating to improve the abrasion and chemical resistance on the surface, enhance to increase lifespan of the belt. Apart from these basic aspects, the further processing of laminating and slitting is also important, we improved our laminating machine to increase the bonding strength of two layers material and in the meantime keep the surface of material as flat as possible after laminating, then we will slit the belt into required sizes, our slitting machine is also improved to make sure the belt continual straight run.

Previous: Research into new coating techniques for thermal insulation material

Next: Innovative application and advantages of PTFE belt in food production line