Research into new coating techniques for thermal insulation material

Update time: 2024-09-24 Views: 778

Description

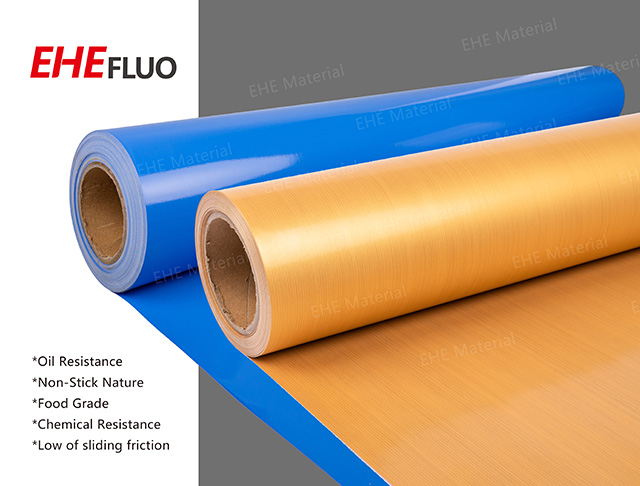

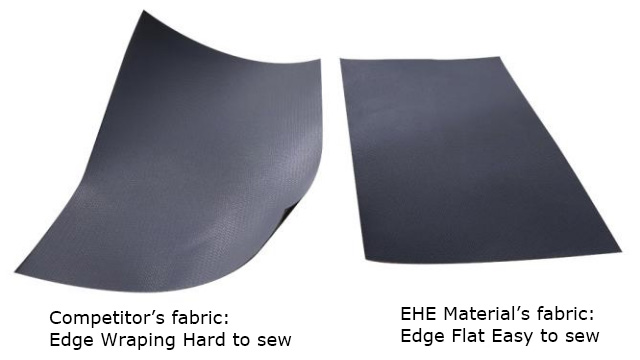

Single-sided Teflon coated fiberglass cloth is no longer an unfamiliar material in the thermal insulation industry. It is a fiberglass fabric material with gray color Teflon coating on one side. Due to its excellent high temperature resistance, optimal checmial corrosion resistance, wear resistance and dust resistance, it is widely used as outer wrapping materials for thermal insulation jackets and covers. Single-sided Teflon coated fiberglass cloth needs to be cut and stitched into specific sized insulation jackets. Since only one side of the material is coated with Teflon coating, this will cause uneven stress on both sides of the material. Sometimes, the material will curl to one side when cut into small sizes, making it difficult to operate during the next sewing process. Our company has developed a new coating method to solve this problem, so that the single-sided PTFE fabric remains flat after cutting, which greatly improved the work efficiency of making removable thermal insulation covers.

Corrosion resistance and wear resistance are also important factors for the insulation jacket material. We’ve been exploring innovative ways to apply the Teflon coating on fiberglass cloth for optimal performance. Our technicians work out a new coating formula and technology to improve the wear and corrosion resistance of the material surface, thereby increasing the service life and safety of the insulation jackets.

Here are some detail features of our Teflon coated fiberglass cloth used in thermal insulation industry:

1. Material composition: A combination of PTFE coating and glass fabric.

2. Insulation performance: Provides effective insulation to prevent heat loss.

3. Removable feature: Allows easy installation, removal, and maintenance.

4. Thickness and weight: Lightweight yet sufficient thickness for insulation.

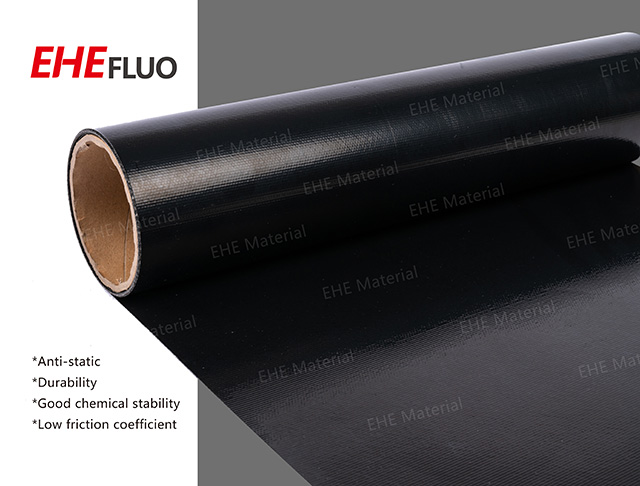

5. Mechanical strength: Resistant to stretching, tearing, and abrasion.

6. Chemical stability: Resistant to chemicals, ensuring long-term use.

7. High-temperature resistance: Can withstand high temperatures up to 550F without degradation.

8. Fire resistance: Offers some degree of fire protection.

9. Impermeability: Prevents the penetration of moisture and fluids.

10. Corrosion resistance: Protects against corrosion and rust.

11. Durability: Long service life with minimal wear and tear.

12. Customizable size and shape: Can be tailored to fit specific applications.

13. Good thermal stability: Retains insulation properties over time.

14. Easy to clean and maintain: Can be simply cleaned when necessary.

15. Cost-effective solution: Provides value for money in terms of insulation.

Teflon coated fiberglass cloth is engineered for the harsh environments in many industrial facilities like acid plants, petrochemical plants and paper mills, the base cloth is non-flammable and remain durable in high temperature environments, the PTFE coating provides outstanding resistance to chemicals and chemical splash, makes the material ideal to be made into equipment covers, expansion joints, splash shields, flange and valve covers, safety clothing. Contact us to know more about our PTFE and silicone coated insulation jacket material.

Next: Innovative application and advantages of PTFE belt in food production line