Unveiling the Versatile Performance and Industrial Applications of Single-Sided Teflon Fabric

Update time: 2025-01-24 Views: 843

Description

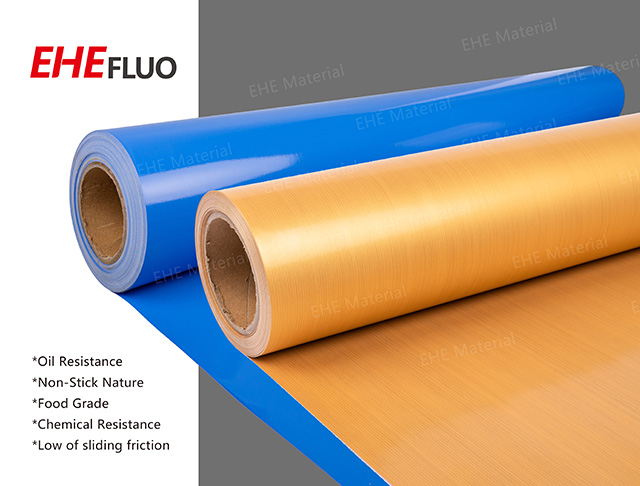

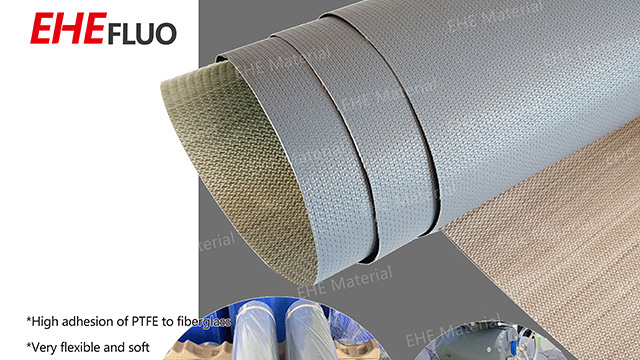

In the realm of high-performance materials, single-sided Teflon fabric stands out due to its unique blend of properties and versatility across diverse industries. This innovative material, characterized by its one-sided coating of Polytetrafluoroethylene (PTFE), offers a multitude of benefits that cater to the needs of various sectors. Let's delve into the exceptional performance characteristics and industrial applications of single-sided Teflon fabric.

Performance Characteristics of Single-Sided Teflon Fabric

- Corrosion Resistance: The PTFE coating on single-sided Teflon fabric provides exceptional corrosion resistance. This makes it ideal for use in harsh chemical environments, where it can maintain stability over extended periods.

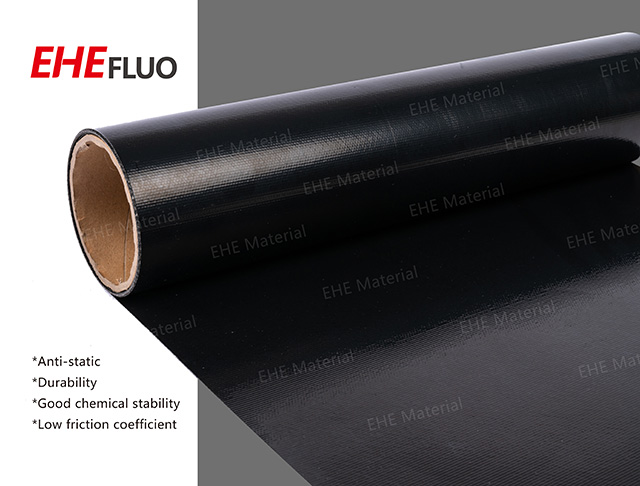

- Low Friction: PTFE is renowned for its extremely low coefficient of friction. This characteristic enables the fabric to reduce wear and friction during sliding or rubbing applications, enhancing efficiency and durability.

- Temperature Resistance: PTFE maintains its properties across a wide temperature range, making single-sided Teflon fabric suitable for extreme environments. It exhibits both high-temperature and low-temperature resistance, ensuring consistent performance under varying conditions.

- Strength and Flexibility: The fiber backing, often made of materials like glass fiber or polyester, offers robust strength and flexibility. This combination ensures that the fabric is durable and easy to handle, suitable for a range of applications.

Industrial Applications of Single-Sided Teflon Fabric

The versatility of single-sided Teflon fabric is evident in its wide range of industrial applications:

- Chemical Industry: In the chemical industry, single-sided Teflon fabric is used as corrosion-resistant gaskets and sealing materials. Its ability to withstand harsh chemicals makes it an indispensable component in various chemical processing equipment.

- Mechanical Industry: In the mechanical industry, the fabric serves as a low-friction sliding component. This reduces wear and tear, enhancing the efficiency and lifespan of machinery.

- Aerospace Industry: The aerospace industry demands materials that can endure extreme temperatures and pressures. Single-sided Teflon fabric meets these requirements, making it suitable for use as auxiliary materials in aircraft composite parts.

- Medical Industry: In the medical field, its corrosion resistance and non-stick properties make it ideal for manufacturing medical devices and equipment.

- Electronic and Electrical Industry: As an electrical insulator, single-sided Teflon fabric protects wires and cables, ensuring the safety and reliability of electrical systems.

- Food Processing Industry: Its non-stick and heat-resistant properties make it perfect for lining baking trays and creating baking papers in the food processing industry.

Market Prospects and Developments

The market for single-sided Teflon fabric is expanding, driven by the growth of downstream industries. According to market research reports, the demand for this material is particularly high in the aerospace industry, where its unique properties are invaluable. As technological advancements continue, the potential applications for single-sided Teflon fabric are likely to broaden further.

In conclusion, single-sided Teflon fabric, with its distinctive material composition and exceptional performance, occupies a pivotal position in modern industrial applications. By leveraging its unique characteristics, we can provide efficient solutions for a variety of industrial scenarios. Whether it's enhancing the durability of machinery, ensuring the safety of electrical systems, or supporting the advancement of aerospace technology, single-sided Teflon fabric is proving to be a versatile and reliable material.

Previous: The Impact of High-Temperature Baking on Teflon High-Temp Tape

Next: Innovative application and advantages of PTFE belt in food production line