The Impact of High-Temperature Baking on Teflon High-Temp Tape

Update time: 2025-01-16 Views: 942

Description

Teflon high-temp tape, renowned for its exceptional heat resistance, non-stick properties, and chemical inertness, plays a crucial role in various industrial applications. However, when subjected to high-temperature baking, this tape can undergo several changes that may affect its performance and usability. This article delves into the consequences of high-temperature baking on Teflon high-temp tape and the factors that contribute to these changes.

Chemical and Physical Transformations

Upon exposure to high temperatures, Teflon high-temp tape may exhibit signs of residue or leakage, commonly referred to as "residual glue." This phenomenon can be observed through tactile inspection or close visual examination, revealing minute remnants on the tape's surface. These residuals can significantly impact manufacturing processes, potentially causing defects in the final product.

The primary reason for such residuals often stems from the tape's inability to meet specific temperature resistance requirements. Typically, Teflon tapes are designed to withstand temperatures ranging from 210°C to 260°C. Therefore, it is imperative to verify the tape's temperature resistance specifications before use to ensure compatibility with the manufacturing process.

Quality Control and Production Factors

Controlling the quality of Teflon high-temp tape before its integration into production lines is paramount. One effective method is to conduct ozone-induced high-temperature selection tests. These tests help identify potential issues related to the tape's material composition and manufacturing process, ensuring only high-quality tapes are used.

Moreover, the production environment itself can influence the tape's performance. Excessively high temperatures in the production line can lead to residual glue formation. Thus, regular checks on temperature sensors are crucial to maintain optimal baking conditions.

During the coating process, adherence to precise heating and curing parameters is essential. Improper heating or excessive coating line speeds can prevent the adhesive and substrate from fully bonding, leading to residual glue upon baking. To mitigate this, manufacturers often allow the coated tape to rest for 2-3 days after the coating process, allowing the adhesive to thoroughly cure and bond with the substrate.

Performance Characteristics and Applications

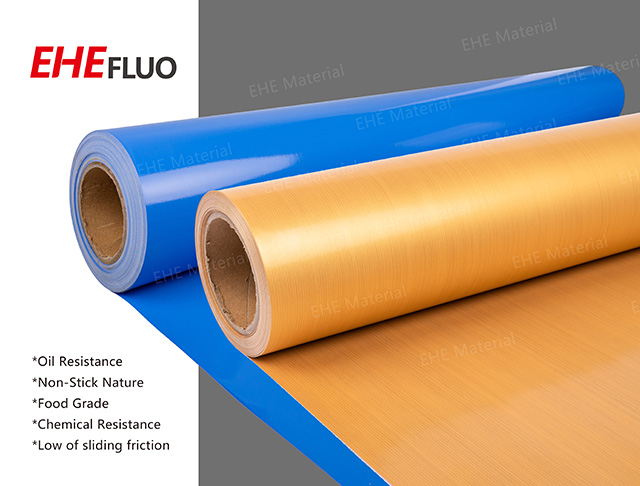

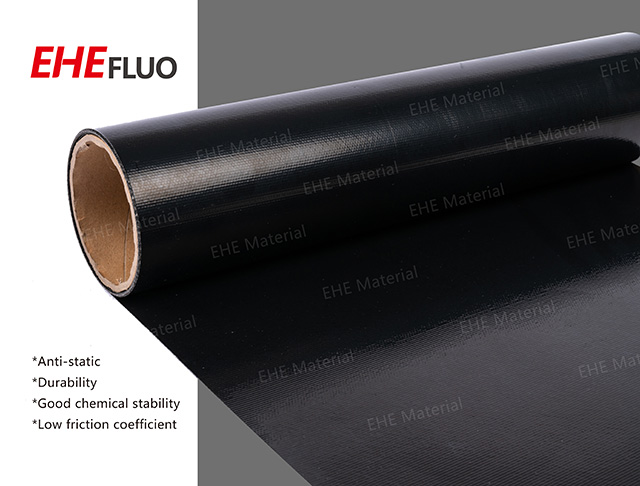

Despite these potential issues, Teflon high-temp tape remains a highly valued material due to its versatile performance characteristics. It exhibits non-stick properties, making it easy to clean and resistant to adhering materials. Additionally, its chemical resistance ensures stability against strong acids, bases, and various organic solvents. Teflon tape also boasts high insulation properties, UV resistance, and antistatic capabilities, making it suitable for a wide range of applications.

In the aerospace industry, for instance, Teflon tape is often used in composite molding processes, where its heat resistance and non-stick properties are critical for smooth mold release and component quality. Similarly, in the food processing sector, its non-reactive surface ensures contamination-free production lines.

Conclusion

In conclusion, while high-temperature baking can affect Teflon high-temp tape, understanding its material properties, adhering to strict quality control measures, and maintaining optimal production conditions can minimize these effects. By doing so, manufacturers can harness the full potential of Teflon tape, ensuring high-quality outputs in various industrial applications. Continuous innovation and rigorous testing remain key to advancing the performance and reliability of Teflon high-temp tape in diverse manufacturing environments.

Previous: Single-Sided Teflon Fabric: A Versatile Material Across Various Industries

Next: Innovative application and advantages of PTFE belt in food production line