Description

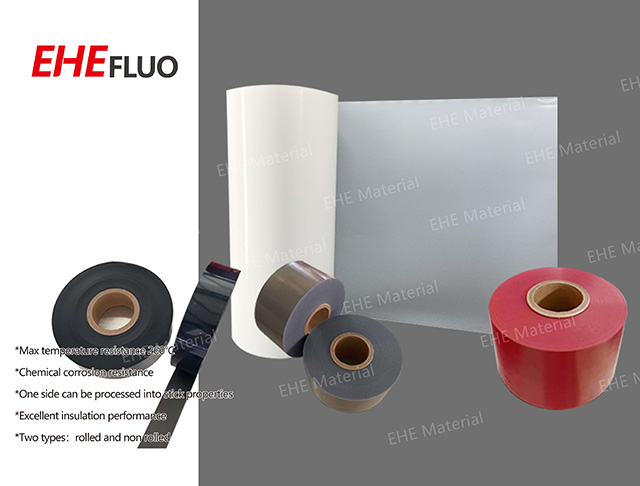

Skived PTFE film is manufactured through a skiving process, resulting in a thin, flexible sheet with outstanding properties. This process involves slicing a block of PTFE to achieve a precise, thin film, characterized by high tensile strength, exceptional chemical resistance, low friction, and excellent dielectric properties.

APPLICATIONS ACROSS INDUSTRIES

The versatility of skived PTFE film enables its use in numerous applications:

1. Electrical Industry: Skived PTFE film is extensively utilized as an insulating material in the electrical industry due to its excellent dielectric properties. It’s applied in cables, capacitors, and other electrical components to ensure safety and efficiency.

2. Industrial Manufacturing: In industrial settings, the film serves as a release liner, preventing adhesion during the manufacturing process. Its non-stick properties make it ideal for molds, chute linings, and conveyor systems.

3. Medical Field: Skived PTFE film finds use in medical applications due to its biocompatibility and resistance to harsh chemicals. It is used in medical tubing, catheters, and as a non-stick surface for medical devices.

4. Aerospace Engineering: The film is employed as a protective barrier against extreme temperatures and chemicals in aerospace applications, contributing to the durability and safety of components.

UNIQUE BENEFITS OF SKIVED PTFE FILM

· Non-Stick Properties: Its non-stick surface ensures easy release of materials, reducing the need for lubricants and preventing adhesion in various applications.

· Chemical and Heat Resistance: Skived PTFE film exhibits exceptional resistance to chemicals and high temperatures, maintaining its integrity in harsh environments.

· Electrical Insulation: Its excellent dielectric properties make it a perfect choice for insulating electrical components, ensuring safety and reliability in electrical applications.

· Flexibility and Strength: The film’s flexibility allows it to conform to various surfaces while maintaining its high tensile strength

T-100 is a skived, virgin grade PTFE film sheet. It is available in thicknesses ranging from 0.0115″ to 0.25″ and in widths of 12″, 24″, 36″, and 48″. PTFE film is supplied either in sheet or continuous roll form. Slit widths are available in thicknesses ranging from 0.001″ to 0.062″ and to the exacting tolerances of the wire and cable, and electronic industries. Custom colors may be available, please call 800.637.6694 for more information.

Technical Parameter

| Performance | Item | Test Method | Unit | Numerical Value |

|

Physical

Property |

Tensile Strength | D638 | Mpa | 14.4-35 |

| Elongation | % | 200-400 | ||

| Proportion | D792 | - | 2.13-2.2 | |

| Hardness (Shore) | D2240 | - | D50-55 | |

| Flexural modulus of elasticity | D790 | GPa | 0.50-0.55 | |

| Tensile Modulus | D638 | GPa | 0.45-0.55 | |

| Compressive Strength | D695 | Mpa | 11.8 | |

| Coefficient of dynamic friction | 0.93Mpa(7kgf/cm3)3m/min | - | 0.10 | |

| Coefficient of static friction | - | - | 0.065 | |

| Impact Strength | D256 | J/M | 160 | |

| Water Absorption Rate | D570 | % | 0.01 | |

| Oxygen Index | D2863 | - | >95 | |

| 3.2mm Thick Combustibility | UL94 | - | V-0 | |

|

Thermal

Performance |

Max Operating Temperature | - | ℃ | ≤260 |

| Min Operating Temperature | - | ℃ | ≥-200 | |

| Melting Point | - | ℃ | 327 | |

| Thermal Conductivity | C177 | W/m.k | 0.25 | |

| Specific Heat | DIN 52612 | J/(℃.g) | 1.05 | |

|

Thermal Deformation Ratio

1.81MPa(18.5kgf/cm2) |

D648 | ℃ | 55 | |

|

Thermal Deformation Ratio

0.45MPa(4.6kgf/cm2) |

121 | |||

|

Coefficient of Thermal

Expansion |

25-100℃ MD | ×10-5/℃ | 11 | |

| 25-100℃ CD | 10 | |||

| 25-150℃ MD | 12 | |||

| 25-150℃ CD | 11 | |||

| 25-200℃ MD | 14 | |||

| 25-200℃ CD | 12 | |||

| 25-250℃ MD | 17 | |||

| 25-250℃ CD | 16 | |||

|

Electrical

Performance |

Dielectric Constant

60HZ(Relative) |

D150 | pF/m |

<18.6

(<2.1) |

| Dielectric Loss Coefficient 60HZ | - | 0.0002 | ||

|

Dielectric Breakdown Strength

(short-term) |

D149 | MV/m | 19 | |

| Anti Arc Characteristics | D495 | Sec | >300 | |

| Volume Resistivity | D257 | Ω.CM | >1018 |