Update time: 2025-07-03 Views: 711

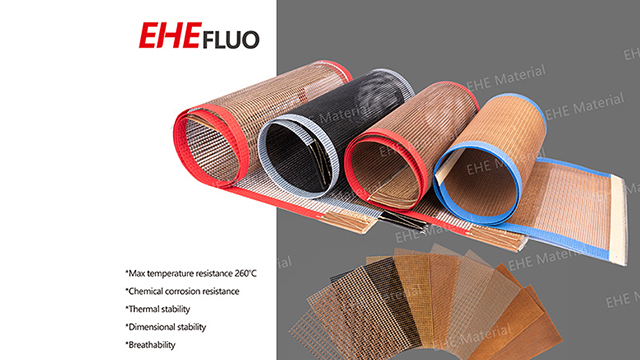

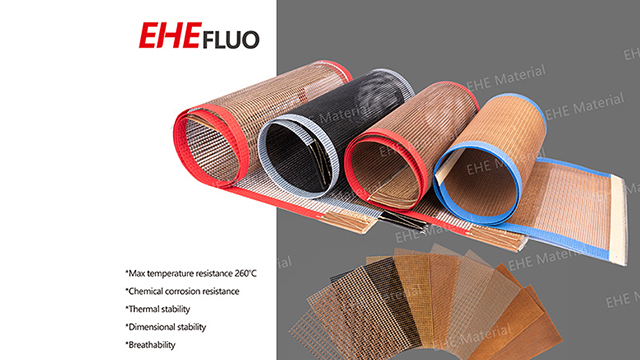

PTFE (polytetrafluoroethylene) coated fiberglass fabric conveyor mesh belts are renowned for their durability, heat resistance, and non-stick properties, making them ideal for industrial applications. Below is a detailed breakdown of their features, applications, and cost-saving potential:

Key Properties of PTFE Coated Fiberglass Fabric

Temperature Resistance:Operates in extreme temperatures (-70°C to +260°C, with some variants enduring up to 300°C).

Maintains dimensional stability even after prolonged exposure to high heat.

Chemical Resistance:

Resistant to acids, alkalis, and organic solvents, making it suitable for corrosive environments.

Non-Stick Surface:

Easy to clean, with minimal material adhesion, reducing downtime for maintenance.

Lightweight yet Strong:

Fiberglass base provides high tensile strength (up to 4,400 N/50mm) while remaining lightweight.

Customization:

Available in various thicknesses (0.08mm–0.65mm), widths (up to 4,000mm), and colors (brown, black, white).

Applications of Conveyor Mesh Belts

Food Industry: Baking, drying, and freezing processes (e.g., tortilla presses, snack food lines).

Textiles: Screen printing, dyeing, and garment fusing.

Packaging: Sealing, shrink wrapping, and labeling machinery.

Industrial: Heat treatment, cooling tunnels, and rubber extrusion.

Environmental: High-temperature dust filtration in cement plants and waste incinerators.

Cost-Saving Benefits

Lower Maintenance:

Non-stick surface reduces buildup, minimizing cleaning frequency and labor costs.

Energy Efficiency:

Excellent heat transfer properties lower energy consumption in drying/curing processes.

Longevity:

Resistant to wear, UV, and moisture, extending belt life compared to rubber or metal alternatives.

Affordable Pricing:Prices range from 2.50–80 per square meter, with bulk discounts for orders over 1,000 square meters.

Example: EHE Composite Materials offers belts at $2.50/m² for orders ≥5,000 m².

Factors Affecting Cost

Material Thickness: Thicker belts (0.3mm–0.65mm) cost more but offer higher durability.

Width/Customization: Wide belts (up to 4,000mm) or specialized features (anti-static, reinforced edges) may increase pricing.

Conclusion

PTFE coated fiberglass fabric conveyor mesh belts offer a cost-effective solution for demanding industrial applications. By prioritizing bulk purchases, standard thicknesses, and Chinese suppliers, businesses can achieve significant savings without compromising performance. Always verify certifications (e.g., ISO, FDA) and request samples to ensure quality.

Previous: Hot Sealing Heat Resistant 4X4mm PTFE Open Mesh Conveyor Belt

Next: Innovative application and advantages of PTFE belt in food production line

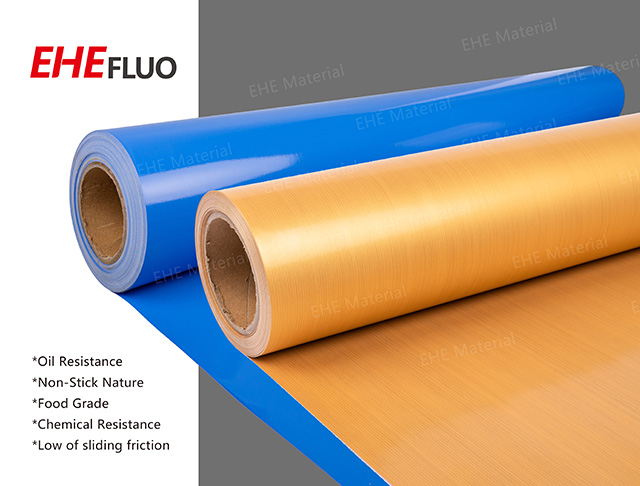

Oil resistant PTFE Fabric is used in a wide variety of industrial food processing applications, including contact belt grills, where high productivity is achieved by cooking between upper and lower heated belts. Laminated fabric is the product of choice whenever processing requires high heat and thr...

More Info

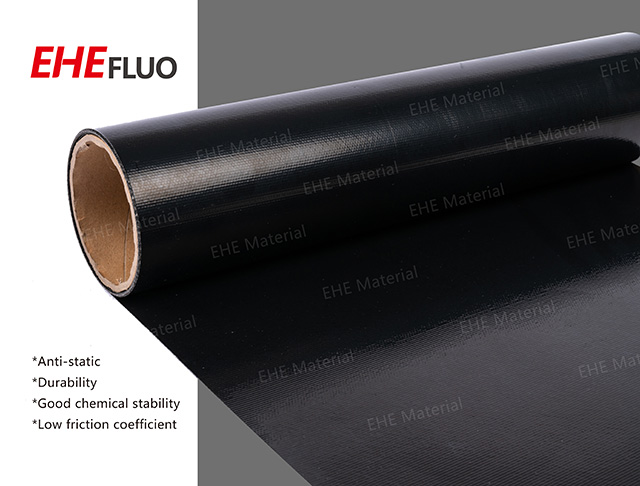

Anti-Static Black PTFE Fabric – The EB series is made by combining premium grade fiberglass fabric, PTFE and carbon or graphite to the coating process. These fabrics can be grounded to eliminate static electricity during operation.

More Info

PTFE glass fabric is a high-performance material created by impregnating woven fiberglass fabric with PTFE, resulting in a durable and versatile product. This combination endows the fabric with remarkable attributes, including heat resistance, low friction, excellent electrical properties, and resis...

More Info