Teflon Mesh Belt Drying and Conveying Equipment: A Global Solution for Industrial Drying Needs

Update time: 2024-12-24 Views: 769

Description

Teflon Mesh Belt Drying and Conveying Equipment: A Global Solution for Industrial Drying Needs

In the vast landscape of global industrial processes, drying technology holds a pivotal role across numerous manufacturing sectors. Teflon mesh belt drying and conveying equipment, distinguished by its unique properties and versatile applications, has emerged as a preferred choice for numerous international enterprises seeking efficient and reliable drying solutions. This article delves into the characteristics, advantages, and global applications of Teflon mesh belt drying and conveying equipment.

Unique Properties of Teflon Mesh Belt Drying and Conveying Equipment

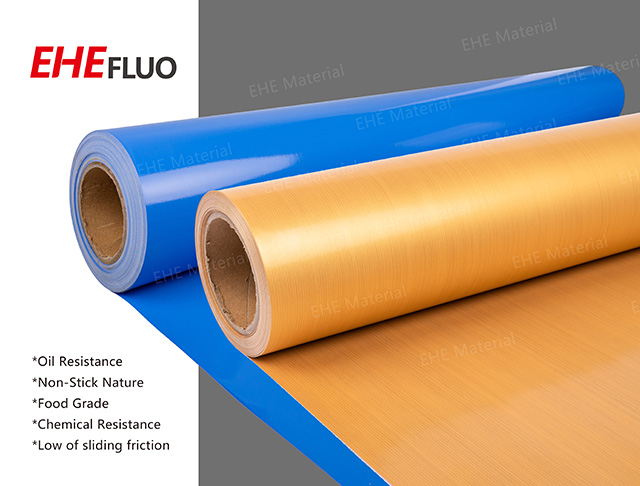

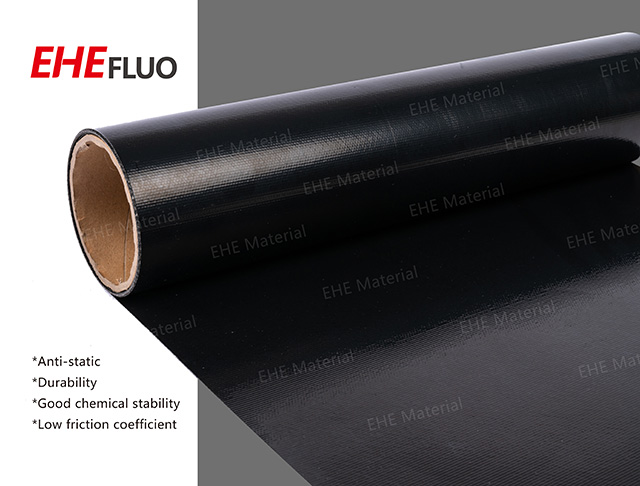

The popularity of Teflon (PTFE) mesh belt drying and conveying equipment in the global market is attributed to its exceptional material properties and innovative design. Teflon, renowned for its high temperature resistance, corrosion resistance, and wear resistance, ensures the stable operation of the conveyor belt under harsh conditions, including high temperatures and acidic or alkaline environments. Furthermore, the mesh structure design enhances the belt's breathability and heat dissipation, while also boosting its strength and load-bearing capacity, making it suitable for handling a wide range of materials and drying requirements.

Global Applications Across Industries

1. Food Industry

Within the food industry, Teflon mesh belt drying and conveying equipment is extensively used in baking, roasting, and drying processes for products such as bread, cookies, and candies. Its heat resistance, corrosion resistance, and ease of cleaning ensure the hygiene and safety of food during the drying process, while also boosting production efficiency.

2. Pharmaceutical Industry

In the pharmaceutical sector, Teflon mesh belt equipment is utilized for drying, sterilizing, and other production processes. Its superior performance guarantees the quality and safety of pharmaceuticals, meeting the industry's stringent hygiene standards and efficiency requirements.

3. Chemical Industry

The chemical industry demands equipment with exceptional corrosion and high-temperature resistance. Teflon mesh belt drying and conveying equipment, with its outstanding chemical stability and heat tolerance, is indispensable in chemical drying applications.

4. Other Industries

Beyond the aforementioned sectors, Teflon mesh belt equipment finds applications in metallurgy, building materials, electronics, textile printing and dyeing, screen printing, UV drying, and more. Its unique properties make it an ideal choice for efficiently and safely completing drying tasks across diverse industries.

Global Market Opportunities and Challenges

As the global economy continues to expand and industrial technology advances, the demand for Teflon mesh belt drying and conveying equipment is growing. Emerging markets and developing countries, with their accelerating industrialization, are particularly eager for efficient and eco-friendly drying equipment.

However, amid intensifying global competition, manufacturers of Teflon mesh belt equipment must innovate and upgrade their products continuously to meet diverse customer needs. Strengthening international cooperation and exchanges to jointly promote innovations and developments in global drying technology is crucial in addressing market challenges.

Conclusion

Teflon mesh belt drying and conveying equipment, with its unique properties and versatile applications, presents strong competitiveness and vast market prospects in the global market. We believe that in future developments, Teflon mesh belt equipment will continue to provide efficient, eco-friendly, and safe drying solutions for the global industrial drying sector, contributing to the sustainable development of enterprises worldwide.

Previous: Application of Teflon Belt in Silkscreen Drying Machines

Next: Innovative application and advantages of PTFE belt in food production line