Application of Teflon Belt in Silkscreen Drying Machines

Update time: 2024-12-09 Views: 844

Description

Teflon belts, known for their unique properties, have found widespread applications across various industries. Among these, their use in silkscreen drying machines stands out prominently due to their ability to enhance efficiency and quality in the printing and drying processes. This article explores the application of Teflon belts in silkscreen drying machines, highlighting their benefits and the reasons behind their popularity.

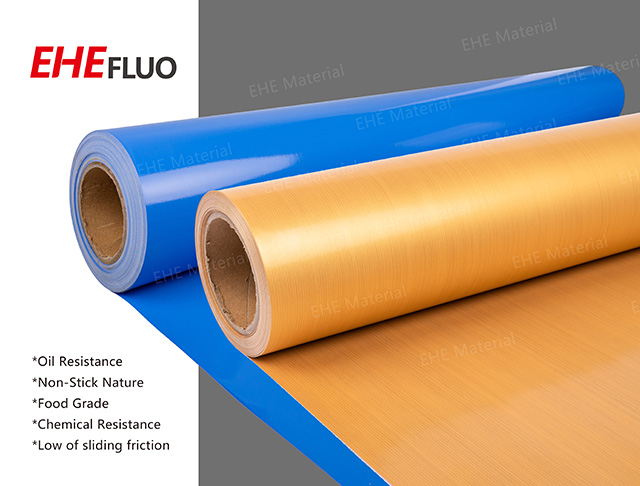

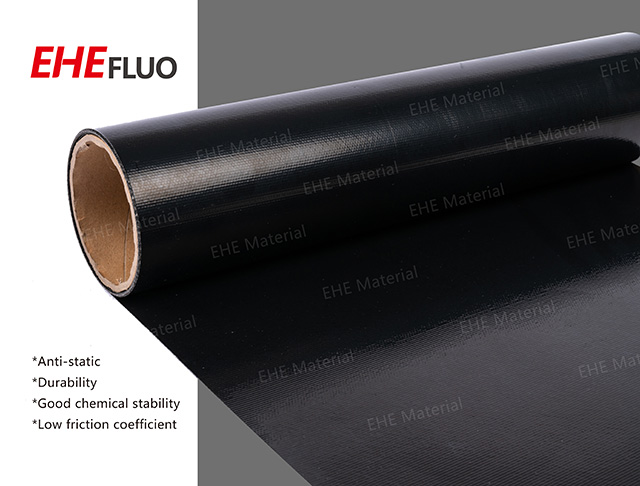

Unique Properties of Teflon Belts

Teflon belts are renowned for their high temperature resistance, non-stick properties, and excellent durability. These belts can withstand temperatures ranging from -70°C to 260°C (some can even operate at up to 300°C), making them suitable for a wide range of industrial applications. Their non-stick surface ensures that ink and other materials do not adhere to the belt, facilitating easy cleaning and maintenance. Additionally, Teflon belts are resistant to aging, chemicals, and UV radiation, further enhancing their suitability for use in silkscreen drying machines.

Application in Silkscreen Drying Machines

In silkscreen printing, the drying process is crucial for ensuring the quality and durability of the final product. Teflon belts play a vital role in this process by providing a smooth, non-stick surface for the ink to dry on. Here are some key benefits of using Teflon belts in silkscreen drying machines:

-

Efficient Heat Transfer:

Teflon belts excel in heat transfer, ensuring that the ink dries quickly and uniformly. This reduces the drying time and improves productivity. -

Non-Stick Surface:

The non-stick properties of Teflon belts prevent ink from adhering to the surface, minimizing the risk of smudging or damaging the print. This ensures that the final product maintains its high quality. -

Easy Cleaning and Maintenance:

Due to their non-stick nature, Teflon belts are easy to clean and maintain. This reduces downtime and maintenance costs, making them a cost-effective choice for silkscreen drying machines. -

Durability and Longevity:

Teflon belts are highly durable and can withstand the rigors of industrial use. They have a long service life, reducing the need for frequent replacements and lowering overall operational costs. -

Versatility:

Teflon belts can be used in a variety of silkscreen drying machines, including UV dryers, convection ovens, and infrared dryers. Their versatility makes them a versatile choice for different printing and drying needs.

Conclusion

In conclusion, Teflon belts offer numerous advantages for use in silkscreen drying machines. Their high temperature resistance, non-stick properties, and durability make them an ideal choice for enhancing the efficiency and quality of the drying process. By utilizing Teflon belts, silkscreen printers can improve productivity, reduce maintenance costs, and produce high-quality prints consistently. As such, Teflon belts are an essential component in the modern silkscreen printing industry, ensuring that the final product meets the highest standards of quality and durability.

Previous: Introduction to Microwave Drying Machine with Drying Mesh Belt

Next: Innovative application and advantages of PTFE belt in food production line