Introduction to Microwave Drying Machine with Drying Mesh Belt

Update time: 2024-12-03 Views: 770

Description

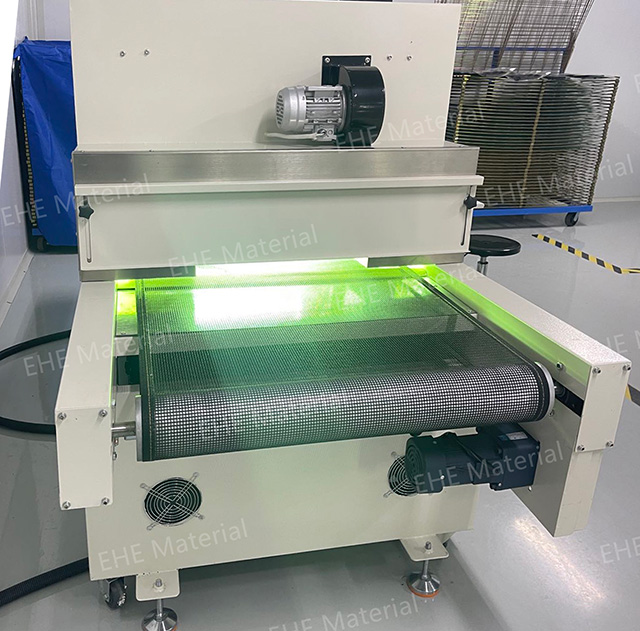

In the realm of industrial drying processes, the microwave drying machine with a drying mesh belt has emerged as a game-changer, revolutionizing the way materials are dried efficiently and effectively. Combining the advanced technology of microwave heating with the versatility of a mesh belt conveyor system, this innovative equipment offers unparalleled advantages in terms of speed, energy efficiency, and product quality.

Operating Principle

The microwave drying machine leverages the principle of microwave radiation to generate heat directly within the material being dried. Unlike conventional heating methods that rely on external heat sources, microwave energy penetrates the material, causing water molecules to vibrate and produce heat internally. This molecular-level heating results in rapid and uniform drying throughout the entire material.

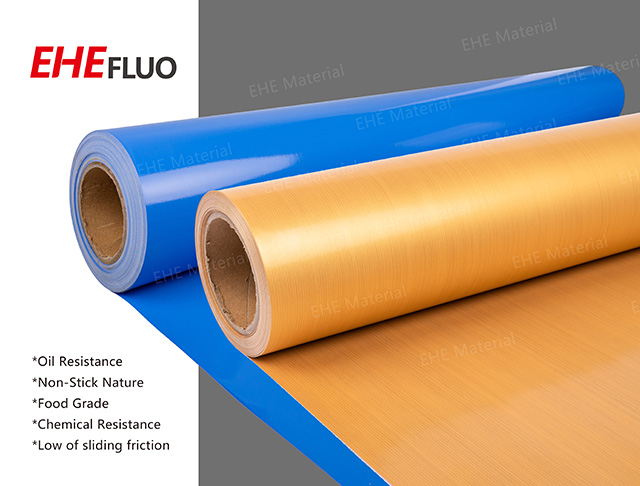

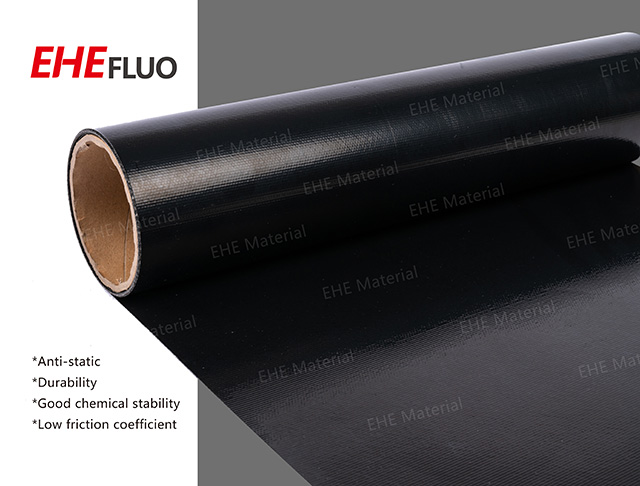

The drying mesh belt serves as the backbone of the system, conveying the material through the microwave cavity at a controlled speed. The mesh design allows for efficient microwave penetration and air circulation, ensuring that moisture is quickly evaporated and removed from the material surface and interior.

Key Features

-

Rapid Drying Speed: Microwave drying significantly reduces drying time compared to conventional methods. The internal heating mechanism accelerates the evaporation of moisture, allowing for faster throughput and shorter production cycles.

-

Uniform Drying: The penetration of microwave energy ensures that the material is dried uniformly from the inside out, eliminating the risk of over-drying or under-drying that can occur with external heating sources.

-

Energy Efficiency: Microwave drying is highly energy-efficient, as it directly converts electromagnetic energy into heat within the material. This reduces energy consumption and operational costs, making it an environmentally friendly option.

-

Versatility: The drying mesh belt can accommodate a wide range of materials and shapes, from powders and granules to flakes and sheets. The adjustable conveyor speed and microwave power levels provide flexibility to meet diverse drying requirements.

-

Ease of Operation and Maintenance: Modern microwave drying machines are equipped with advanced control systems that allow for precise monitoring and adjustment of drying parameters. The modular design of the mesh belt conveyor system simplifies maintenance and cleaning.

Applications

The microwave drying machine with a drying mesh belt finds widespread application in various industries, including food processing, pharmaceuticals, chemicals, and ceramics. In the food industry, it is ideal for drying fruits, vegetables, snacks, and spices, preserving their natural color, flavor, and nutrients. In the pharmaceutical sector, it ensures the gentle drying of active ingredients and tablets without compromising their potency or stability.

Conclusion

The microwave drying machine with a drying mesh belt represents a significant advancement in industrial drying technology. Its combination of rapid drying speed, uniform heating, energy efficiency, and versatility makes it an ideal solution for a wide range of applications. By leveraging the power of microwave energy and the efficiency of a mesh belt conveyor system, this innovative equipment is poised to transform the way materials are dried in the modern industrial landscape.

Previous: Application of Single-sided Teflon Fabric in Semiconductor insulation and Electr...

Next: Innovative application and advantages of PTFE belt in food production line