Update time: 2025-10-14 Views: 54

Teflon seamless belts, also known as seamless fusing machine belts or PTFE-coated conveyor belts, are high-performance industrial materials engineered for extreme environments. Made by coating high-strength fiberglass or Kevlar (aramid) fabrics with polytetrafluoroethylene (PTFE, Teflon) resin, these belts combine durability, thermal stability, and chemical resistance.

Key Product Features

Exceptional Temperature ResistanceOperates from -196°C to 360°C without deformation or cracking.

Tests show no loss of strength after 200 days at 250°C or 120 hours at 350°C.

Low Friction & Non-Stick SurfaceCoefficient of friction as low as 0.05–0.1, enabling smooth material handling.

Non-adhesive properties simplify cleaning of oils, resins, and other residues.

Chemical & Corrosion Resistance

Withstands strong acids, alkalis, solvents, and even aqua regia (a mix of nitric and hydrochloric acids).

Dimensional Stability

Extension coefficient <5‰, ensuring minimal stretching under load.

Electrical Insulation & Safety

Dielectric constant of 2.6, with flame-retardant and anti-static properties.

Mechanical Strength

High tensile strength (e.g., 1,500 N/cm for 0.9mm-thick belts) supports heavy-duty applications.

Applications Across Industries

Food Processing & PackagingUsed as baking mats, microwave pads, and conveyor belts for frozen foods (rice, candies), tobacco, and tea drying lines.

Compliant with FDA standards for direct food contact.

Textile & Printing

Ideal for dyeing, printing, and UV curing machines due to heat resistance and non-stick surfaces.

Chemical & Petrochemical

Corrosion-resistant linings for pipelines, reactors, and waste gas desulfurization systems.

Electronics & Electrical

Insulating sleeves for cables, high-frequency circuit boards, and thermal packaging.

Pharmaceuticals & Heat Treatment

Transport belts for drug manufacturing, rubber vulcanization, and industrial heat treatment processes.

Automotive & Construction

Anti-rust coating transport belts for car parts and flame-retardant materials for building insulation.

Technical Specifications

|

Parameter

|

Details

|

|

Material

|

PTFE-coated fiberglass/Kevlar

|

|

Thickness

|

0.08mm–0.90mm (customizable)

|

|

Width

|

Up to 4,000mm

|

|

Temperature Range

|

-196°C to 360°C

|

|

Tensile Strength

|

130–1,500 N/cm (depending on thickness)

|

|

Colors

|

Brown, black, white, silver

|

|

Coating Options

|

Double-sided, single-sided, anti-static

|

Why Choose Teflon Seamless Belts?

Longevity: Resistant to aging, UV, and mechanical wear.

Cost-Efficiency: Reduces downtime and maintenance costs.

Versatility: Adaptable to custom sizes and coatings.

Global Compliance: Meets international standards for food, safety, and environmental protection.

SEO Optimization Tips for Exporters

Keyword Targeting: Use phrases like "high-temperature PTFE belts," "chemical-resistant conveyor belts," or "food-grade Teflon belts."

Content Structure: Highlight applications in industry-specific sections (e.g., "Teflon Belts for Textile Machinery").

Technical Backlinks: Partner with engineering blogs or industrial forums to link to your product pages.

Multilingual Support: Offer datasheets in Spanish, Arabic, and Russian to tap into emerging markets.

Contact Us for Custom Solutions

Tailor Teflon seamless belts to your needs—whether for ultra-high temperatures, anti-static requirements, or food-grade compliance. Our team provides global shipping and technical support.

Previous: Innovative application and advantages of PTFE belt in food production line

Next: No

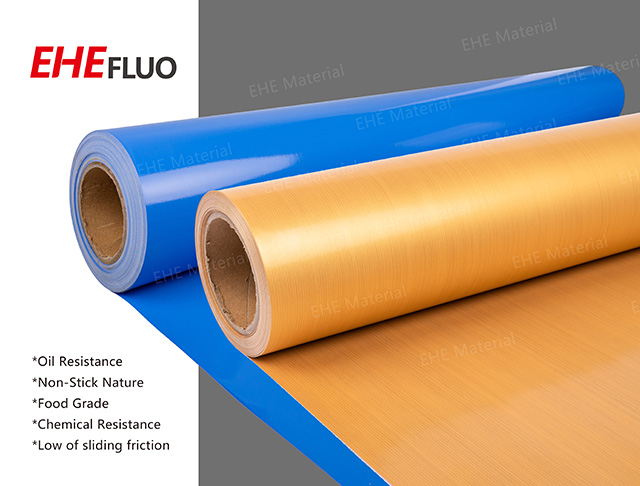

Oil resistant PTFE Fabric is used in a wide variety of industrial food processing applications, including contact belt grills, where high productivity is achieved by cooking between upper and lower heated belts. Laminated fabric is the product of choice whenever processing requires high heat and thr...

More Info

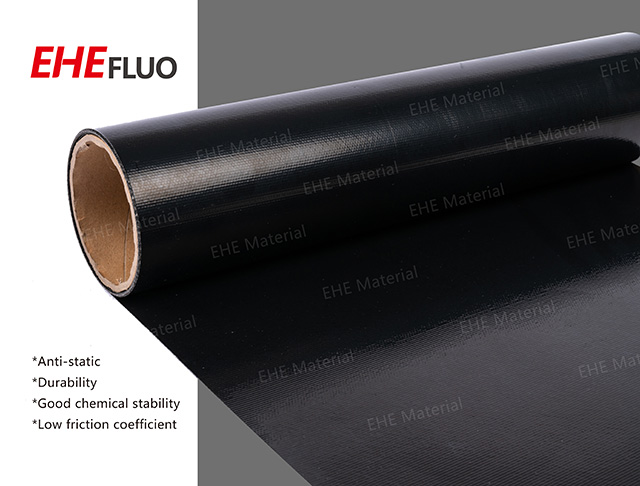

Anti-Static Black PTFE Fabric – The EB series is made by combining premium grade fiberglass fabric, PTFE and carbon or graphite to the coating process. These fabrics can be grounded to eliminate static electricity during operation.

More Info

PTFE glass fabric is a high-performance material created by impregnating woven fiberglass fabric with PTFE, resulting in a durable and versatile product. This combination endows the fabric with remarkable attributes, including heat resistance, low friction, excellent electrical properties, and resis...

More Info