How to use PTFE Coated Fiberglass Fabric in Solar Industry?

Update time: 2024-09-24 Views: 949

Description

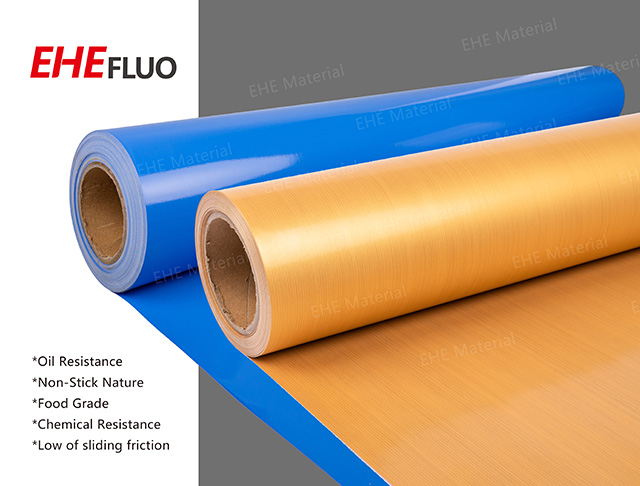

Solar panel lamination machine manufacturers often provide a set of Teflon coated fiberglass cloth together with the machine, this cloth is heat resistant and non-stick, used both as belting, and as protective coverings for the lamination press surfaces. Main function of PTFE coated fiberglass fabric is to prevent the melted EVA from sticking to the rubber plate and the heating plate. Once the EVA is stuck to the rubber sheet and heating plate, it will be difficult to remove.

How to apply PTFE Coated Fiberglass Fabric correctly?

Each solar laminating machine needs to be equipped at least two sets (4 sheets) of solar lamination fabrics. When the laminating machine presses the solar photovoltaic module, PTFE laminated fabric is placed on the upper and bottom layer of the photovoltaic module as a cover cloth and a backing cloth, its non-stick surface helps to prevent EVA film and other substances from sticking to the machine under high temperature.

PTFE fabric for lamination process is resuable, but after each use, please don't reuse it immediately, put it aside and wait for the fabric to cool down completely, and then completely remove the EVA from it, don’t damage its surface when cleaning. If the EVA on the laminated fabric cannot be completely removed, the EVA remains on this fabric will be transferred to the glass of the solar module when it is used again. At this time, small EVA particles will be left on the glass no matter what is used to clean it, when this kind of panel is used outdoors, these small EVA particles will re-melt and stick to the glass and absorb dust on the glass. This dust cannot be removed, and sometimes the dust blocks the cells, creating a long-term hot spot effect.

Besides as release sheet for laminating process, PTFE coated fiberglass fabric is also used as conveyor belt in the automatic laminating machines. Since the laminating machine is evacuated, in order to prevent the conveyor material from sucking the board, the surface of PTFE conveyor belt used this this process is required to be textured which will helps to increase friction force in the meanwhile. Please note the tension of the conveyor belt should not be too large during conveying.

Main Features of PTFE Coated Fiberglass Fabric

-

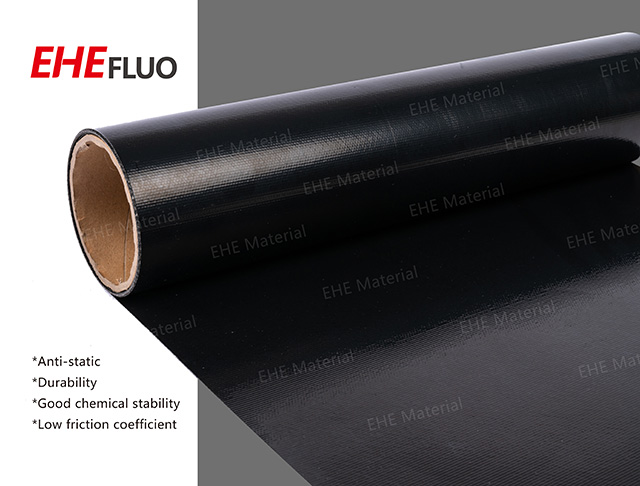

Dimension stable size, high tensile strength, elongation coefficient less than 5‰

-

Good temperature resistance, continuous working temperature -70-260℃

-

Low surface friction coefficient, good insulation

-

Anti-stick surface, easy to clean EVA colloid, stains or other attachments attached to its surface

-

Good corrosion resistance, resistance to various strong acids and alkalis

-

Reusable and aging resistance

Previous: Improve Lifespan of PTFE Teflon Tabber Stringer Belt

Next: Innovative application and advantages of PTFE belt in food production line