What are the different types of PTFE coated fiberglass fabrics?

Update time: 2025-05-23 Views: 763

Description

PTFE (polytetrafluoroethylene) coated fiberglass fabrics are versatile materials renowned for their heat resistance, chemical inertness, and non-stick properties. These fabrics, engineered by combining a woven fiberglass substrate with a PTFE coating, come in multiple variants tailored to specific industrial, commercial, and specialized applications. Below is a detailed breakdown of the primary types, their unique attributes, and how to select the right option for your needs.

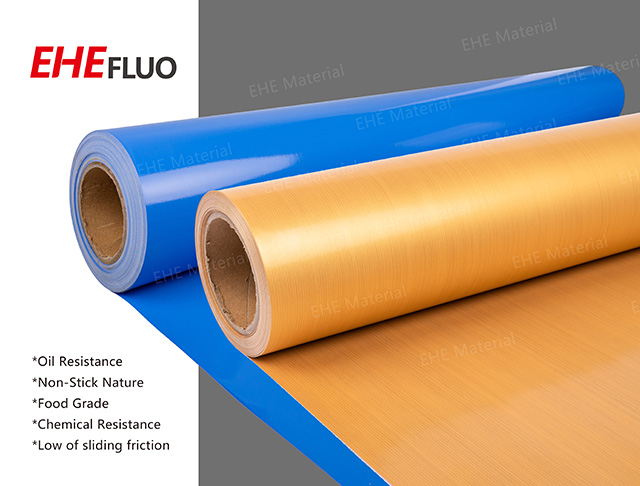

1. Standard PTFE Coated Fiberglass Fabrics

Characteristics:

Temperature Range: Withstands continuous temperatures up to 500°F (260°C).Thickness: Typically ranges from 0.08mm to 1.5mm.

Surface: Smooth PTFE coating on one or both sides.

Advantages:

Cost-effective solution for general-purpose applications.

Excellent non-stick surface for easy release of adhesives, resins, and food products.

Flexible at room temperature for easy handling.

Typical Applications:

Food Industry: Baking mats, conveyor belts for freezers, dryers, and ovens.

Packaging: Heat-sealing bars and release sheets for laminating processes.

Textiles: Non-stick liners for ironing and dyeing machines.

2. High-Temperature PTFE Coated Fabrics

Characteristics:Temperature Resistance: Endures short-term exposure up to 600°F (315°C).

Reinforced Construction: Thicker fiberglass weave or additional PTFE layers for durability.

Advantages:

Ideal for extreme heat environments like aerospace composites curing or metal processing.

Resists degradation from thermal cycling.

Typical Applications:

Aerospace: Mold release sheets for carbon fiber composite curing.

Automotive: Heat shields and exhaust system insulation.

Metalworking: High-temperature conveyor belts for annealing furnaces.

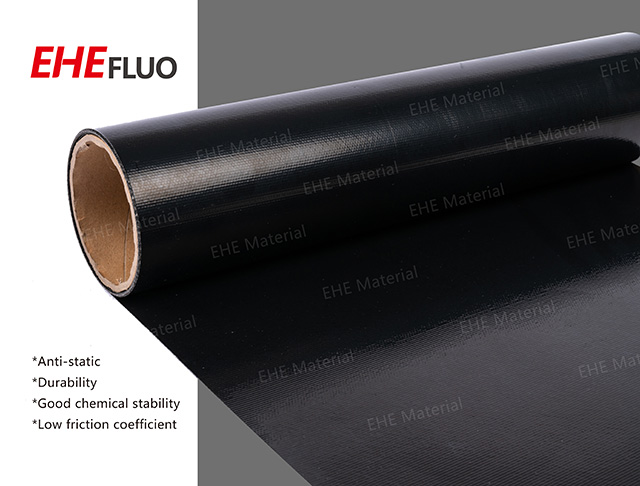

3. Antistatic (Conductive) PTFE Coated Fabrics

Characteristics:Surface Resistance: Embedded conductive fibers or coatings to dissipate static electricity (10⁶–10⁹ ohms/sq).

PTFE Coating: Maintains non-stick properties while preventing static buildup.

Advantages:

Critical for explosive environments or electronics manufacturing.

Reduces dust attraction in cleanrooms.

Typical Applications:

Electronics: ESD-safe conveyor belts for PCB assembly.

Chemical Plants: Liners for tanks handling flammable liquids.

Pharmaceuticals: Anti-static release films for tablet compression.

4. Heavy-Duty PTFE Coated Fabrics

Characteristics:Thicker Fiberglass Base: Up to 1.5mm thickness for enhanced tear resistance.

Dual-Coated PTFE: PTFE on both sides for double-sided protection.

Advantages:

Withstands abrasion, punctures, and heavy loads.

Longer lifespan in high-stress applications.

Typical Applications:

Construction: Architectural membranes for tensile structures.

Mining: Wear-resistant liners for chutes and hoppers.

Agriculture: Durable covers for grain drying systems.

5. Silicone-Adhesive Backed PTFE Fabrics

Characteristics:Pressure-Sensitive Adhesive (PSA): Silicone adhesive layer for easy bonding to metals, plastics, or other fabrics.

Release Liner: Protective paper backing for adhesive until application.

Advantages:

Simplifies installation in hard-to-reach areas.

Reusable and leaves no residue upon removal.

Typical Applications:

Heat Sealing: Adhesive-backed gaskets for packaging machinery.

Automotive: Insulation pads for under-hood components.

HVAC: Ductwork seals resistant to moisture and chemicals.

6. Food-Grade PTFE Coated Fabrics

Characteristics:FDA Compliance: Approved for direct contact with food (FDA 21 CFR 177.1550).

Smooth Finish: Easy-to-clean surface for hygiene-critical environments.

Advantages:

Non-toxic and resistant to oils, fats, and acids.

Withstands repeated washdowns and sterilization.

Typical Applications:

Baking: Non-stick oven liners and dough sheeting belts.

Meat Processing: Conveyor belts for smoking and cooking chambers.

Confectionery: Release sheets for chocolate and candy molds.

7. Double-Sided PTFE Coated Fabrics

Characteristics:PTFE Coating on Both Sides: Provides uniform non-stick properties on both surfaces.

Symmetrical Construction: Balanced performance for dual-sided exposure.

Advantages:

Ideal for applications requiring release on both sides, such as laminating presses.

Reduces material waste by eliminating the need for separate liners.

Typical Applications:

Composite Manufacturing: Release films for prepreg curing.

Printing: Double-sided plates for offset printing presses.

Textiles: Calender rolls for synthetic fabric finishing.

How to Choose the Right PTFE Coated Fiberglass Fabric?

Temperature Requirements:Select high-temperature variants for applications exceeding 500°F (260°C).

Chemical Exposure:

Confirm compatibility with acids, solvents, or bases using a chemical resistance chart.

Mechanical Stress:

Opt for heavy-duty types if abrasion or puncture resistance is critical.

Static Control:

Choose antistatic grades for electronics or explosive environments.

Regulatory Compliance:

Verify FDA or REACH certifications for food/medical use.

Customization:

Work with manufacturers for tailored thicknesses, widths, or adhesive options.

Maintenance and Longevity

Cleaning: Use mild detergents and soft brushes to avoid scratching the PTFE surface.Inspection: Regularly check for tears or coating delamination.

Storage: Keep rolls flat in dry conditions to prevent warping.

Conclusion

PTFE coated fiberglass fabrics offer a spectrum of solutions for industries demanding reliability in harsh conditions. By understanding the nuances of each type—from high-temperature resistance to antistatic properties—you can optimize performance, safety, and cost-efficiency in your applications. Whether you’re designing a heat-resistant conveyor system or a food-safe processing line, the right PTFE fabric ensures durability and precision.Previous: PTFE Coated Fiberglass Fabrics: The Ultimate Guide to High-Performance Materials

Next: Innovative application and advantages of PTFE belt in food production line