Application of PTFE belts in the rubber conveyor belt industry

Update time: 2025-02-20 Views: 459

Description

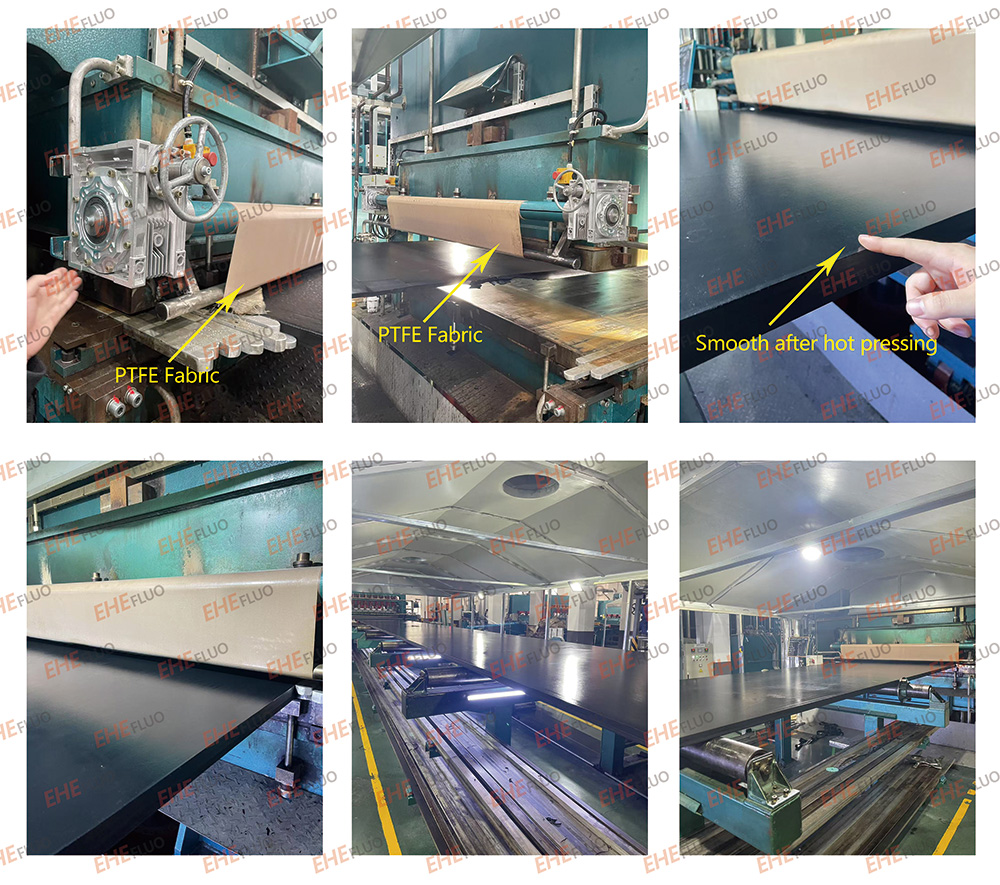

In the production process of rubber conveyor belts, the vulcanization process often encounters adhesion between the upper and lower pressure plates and the rubber, requiring workers to polish the surface defects in the later stage. Teflon belts, as a revolutionary material, are reshaping the face of this industry with their outstanding performance advantages.

Teflon belts have an extremely low coefficient of friction and high temperature resistance, which is another major advantage of Teflon belts. In a high temperature environment of 300 ℃, PTFE belts can still maintain stable physical properties, which makes them outstanding in the field of high-temperature processing. In terms of anti adhesion, PTFE belts also perform well. Its surface is not easily adhered to materials, which is particularly important in the production process of rubber conveyor belts. After a certain rubber conveyor belt manufacturing enterprise used PTFE belts, the residual rubber material decreased by 90%, the cleaning and maintenance time shortened by 70%, and the surface of the rubber conveyor belt became smoother and more beautiful, greatly improving the operating efficiency of the production line.

In the rubber conveyor belt industry, it is driving innovation in production processes, improving product quality, and reducing production costs. In the future, with further optimization of PTFE materials, their application prospects in the rubber conveyor belt industry will be even broader.

Previous: Application of PTFE belt in the Production Process of Thermoplastic Honeycomb Pa...

Next: Innovative application and advantages of PTFE belt in food production line