Description

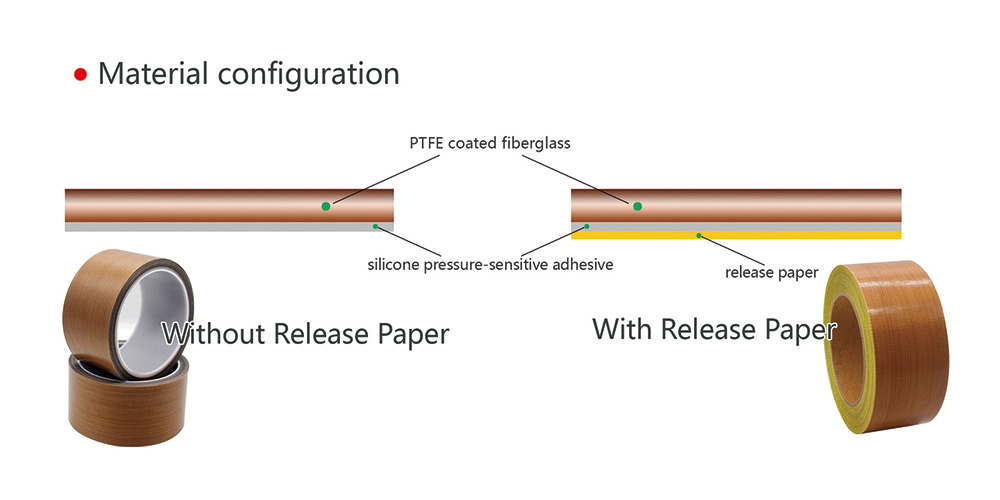

PTFE fiberglass adhesivet ape is a high-performance adhesive tape formed by impregnating woven fiberglass fabric with PTFE. This combination results in a tape that possesses remarkable properties such as heat resistance, electrical insulation, chemical inertness, and a non-stick surface.

According to the requirements of adhesive strength and temperature resistance, this tape is divided intoPTFEacrylicadhesivetapeand PTFEsiliconeadhesivetape.

APPLICATIONS ACROSS INDUSTRIES

The versatility of PTFE glass tape allows for its application in diverse industries:

1. Electrical and Electronics Industry: The tape serves as an insulator for wiring, cables, and electrical components due to its excellent dielectric properties. It ensures electrical safety and reliability.

2. Packaging and Sealing: PTFE glass tape’s non-stick nature and heat resistance make it ideal for sealing machines, ensuring smooth and clean operations in packaging industries.

3. Heat Sealing and Welding: It is utilized in heat sealing equipment to prevent sticking during welding and sealing processes, maintaining the integrity of the materials being joined.

4. Aerospace and Automotive Sectors: The tape finds use in these industries for wire harnessing, providing protection and insulation against heat and harsh conditions.

UNIQUE BENEFITS OF PTFE GLASS TAPE

· Heat Resistance: PTFE glass tape can withstand high temperatures without losing its physical or electrical properties, making it suitable for demanding applications.

· Non-Stick Surface: The non-stick nature of the tape prevents adhesion, allowing for smooth and clean operations in various applications.

· Chemical Inertness: It is highly resistant to various chemicals, ensuring stability and reliability even in harsh environments.

· Electrical Insulation: The tape’s dielectric properties make it an excellent insulator for electrical components, ensuring safety in electrical applications.

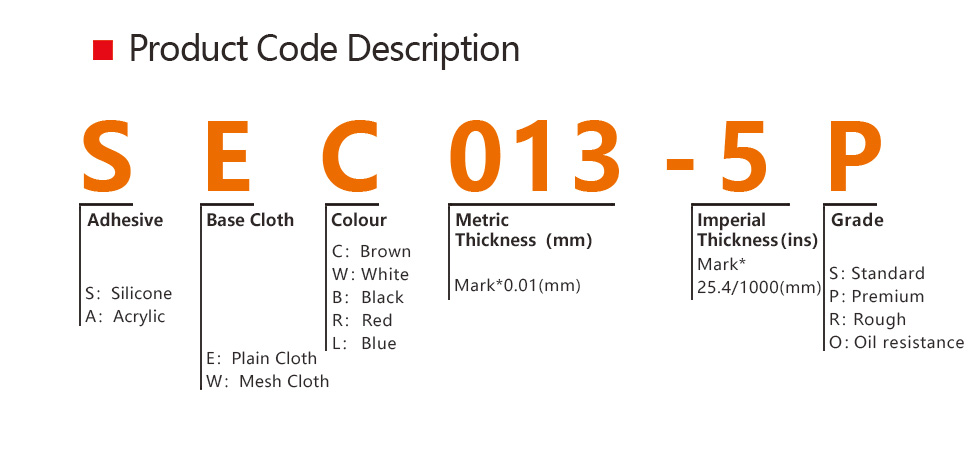

Technical Parameter

| Technical parameters of organic silicon fiberglass tape | ||||||||

| Grade | Code |

Backing Thickness

(ins/mm) |

Total Thickness with adhesive

(ins/mm) |

Standard Width

(mm) |

Weight

(g/㎡) |

Tensile Strength

(N/25cm) |

Breakdown Voltage

(Kv) |

Adhesion

(N/cm/oz./in) |

|

Silicone/

Premium |

SEC013-5P | 0.003/0.08 | 0.005/0.13 | 1000/1250 | 210 | 360 | 3.9 | 4.4/40 |

| SEC016-6P | 0.005/0.115 | 0.006/0.16 | 1000/1250 | 280 | 530 | 4.4 | 4.4/40 | |

| SEC018-7P | 0.006/0.130 | 0.007/0.18 | 1000/1250 | 320 | 730 | 4.5 | 4.4/40 | |

| SEC020-8P | 0.007/0.155 | 0.008/0.20 | 1000/1250 | 350 | 820 | 4.6 | 4.4/40 | |

| SEC023-9P | 0.007/0.180 | 0.009/0.23 | 1000/1250 | 420 | 880 | 4.8 | 4.4/40 | |

| SEC030-12P | 0.010/0.250 | 0.012/0.30 | 1000/1250 | 540 | 1050 | 6.2 | 4.4/40 | |

| SEC035-14P | 0.012/0.300 | 0.014/0.35 | 1000/1250 | 630 | 1450 | 6.3 | 4.4/40 | |

| Technical parameters of acrylic fiberglass tape | ||||||||

| Grade | Code |

Backing Thickness

(ins/mm) |

Total Thickness with adhesive

(ins/mm) |

Standard Width

(mm) |

Weight

(g/㎡) |

Tensile Strength

(N/25cm) |

Breakdown Voltage

(Kv) |

Adhesion

(N/cm/oz./in) |

|

Acrylic/

Premium |

AEC013-5P | 0.003/0.08 | 0.005/0.13 | 1000/1250 | 210 | 360 | 3.9 | 5/45 |

| AEC018-7P | 0.006/0.130 | 0.007/0.18 | 1000/1250 | 320 | 730 | 4.5 | 5/45 | |

| AEC023-9P | 0.007/0.180 | 0.009/0.23 | 1000/1250 | 420 | 880 | 4.8 | 5/45 | |

| AEC030-12P | 0.010/0.250 | 0.012/0.30 | 1000/1250 | 540 | 1050 | 6.2 | 5/45 | |

| AEC035-14P | 0.012/0.300 | 0.014/0.35 | 1000/1250 | 630 | 1450 | 6.3 | 5/45 | |