Description

PTFE(Teflon) mesh conveyor belt is made of suspended polytetrafluoroethylene(commonly known as plastic king PTFE) emulsion as raw material, impregnated with high-performance glass fiber mesh or aramid fiber mesh. It is a new high-performance, multi-purpose composite material product.

PTFE coated mesh belts offer excellent nonstick properties and dimensional stability, it is widely used in papermaking, food processing, environmental protection, printing and dyeing screen print, clothing, chemicals, glass, pharmaceutical press belts, electronics, insulation, grinding wheel slicing, mechanical heat sealing, and other fields.

RELEASE PROPERTIES

The release characteristics of PTFE are superior to those of any other high temperature material. This non-stick property is retained over a full range of operating temperatures.

PERMEABILITY

Our PTFE Belts combine a maximum amount of open area with good mechanical strength. The result is a very high level of controlled air flow through the belt, maximizing the rate of drying.

DIMENSIONAL STABILITY

The woven reinforcement results in an elongation of approximately 1% under normal mechanical loading, even at temperatures of 550°F. Length distortion is exceptionally low, while width rigidity and stability are enhanced by the high-modulus of the reinforcement.

THERMAL STABILITY

Our PTFE Belts may be used continuously at temperatures up to 550°F without reducing its performance.

DYNAMIC STRENGTH

Our PTFE Belts have been subjected to static and dynamic tests which indicate that it can withstand all normal operating conditions affecting service life.

CHEMICAL RESISTANCE

PTFE Belt surfaces are unaffected by most chemicals and solvents.

SUPPORT, DRIVING, TENSIONS AND GUIDING

The excellent dimensional stability of EHE brand conveyor belts makes it possible to use simple systems for support, tensioning. driving and guiding.

Nevertheless, if belts are to be trouble-free throughout their full working life, it is essential that the arrangements for tensioning, driving and guiding be specifically designed for the particular application.Accordingly, we advise that customers seek the advice of their area Sales Manager.

SUPPORT

Steel sliding plate,steel chevrons or rollers are all suitable forms of support for EHE Performance Plastics belts.

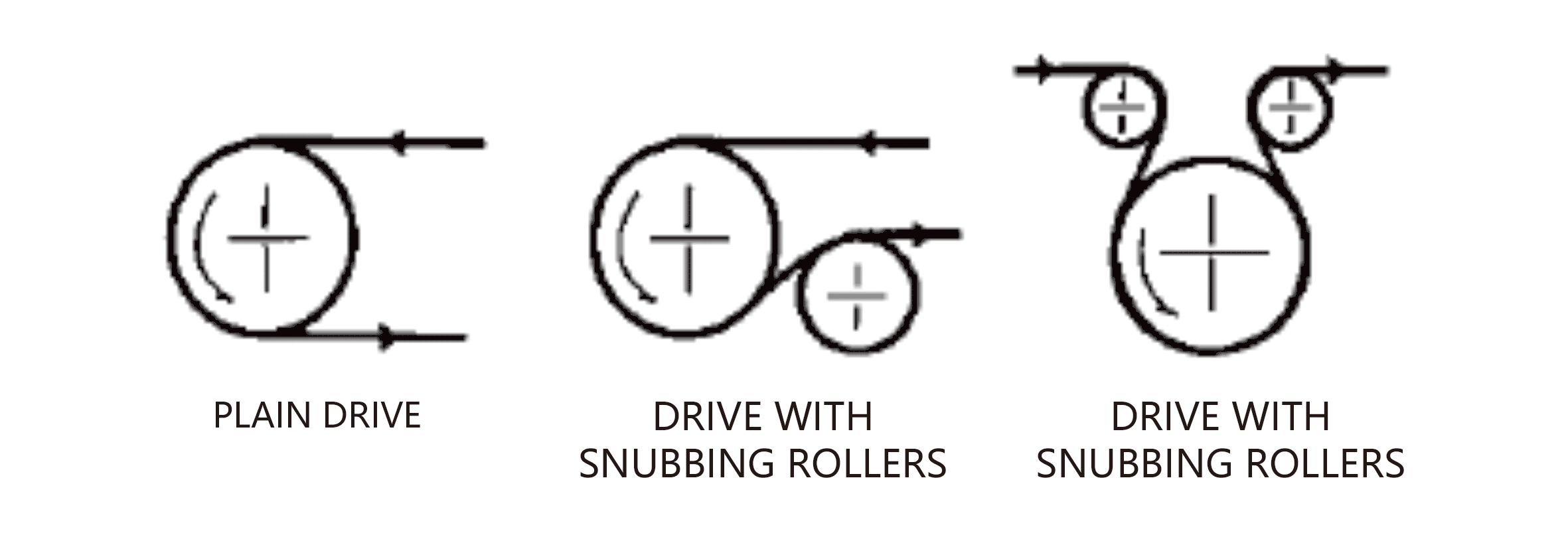

DRIVING

A single drive roller with a flat face and suitable high friction covering will meet the requirements of most applications.

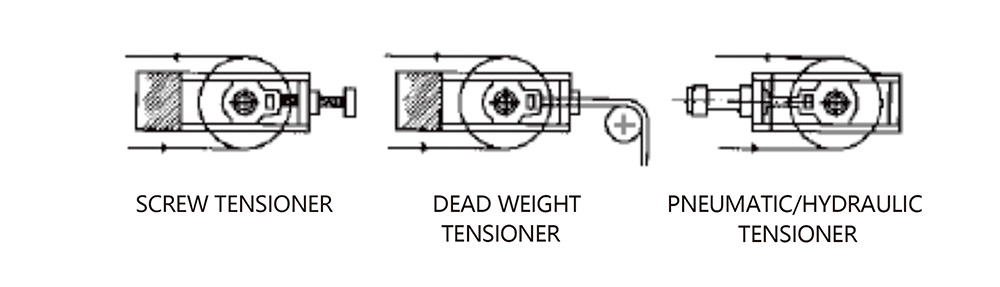

TENSIONING

Tensioning can be achieved by quite simple means as EHE Performance Plastics belts undergo very little expansion or contraction during their working life.

Technical Parameter

| Grade | Code | Colour |

Mesh Size

(mm) |

Standard Width

(mm) |

Weight

(g/㎡) |

Tensile Strength

(N/cm) |

Antistatic

Index |

|

| Warp | Fill | |||||||

| Double weft | WC01-D | Brown | 1*1 |

1000/1500/2050/2600

2800/3200/3650/4000 |

440 | 446 | 330 | —— |

| WB01-D | Black | 1*1 |

1000/1500/2050/2600

2800/3200/3650/4000 |

440 | 446 | 330 | 10^7-10^5 | |

| WC025-D | Brown | 2*2.5 |

1000/1500/1800/2000

3000/3600 |

720 | 290 | 400 | —— | |

| WB025-D | Black | 2*2.5 |

1000/1500/1800/2000

3000/3600 |

720 | 290 | 400 | 10^7-10^5 | |

| WC03-D | Brown | 3*3 |

1000/1500/1700/2050

2500/2700/3200/3400

|

710 | 320 | 435 | —— | |

| WC04-D | Brown | 4*4 |

1000/1500/1700/2050

2500/2700/3200/3400 3600/3800/4000 |

580 | 360 | 500 | —— | |

| WB04-D | Black | 4*4 |

1000/1500/1700/2050

2500/2700/3200/3400 3600/3800/4000 |

580 | 360 | 500 | 10^7-10^5 | |

| WC04-DD | Brown | 4*4 |

1000/1500/1700/2500

2700/3200/3800/4000 |

760 | 410 | 650 | —— | |

| WC04-DDD | Brown | 4*4 |

1000/1500/1700/2050

2500/2700/3200 |

1180 | 480 | 940 | —— | |

| WC08-D | Brown | 8*8 | 1000/1400/2000/2800 | 520 | 350 | 480 | —— | |

|

Single

weft |

WC04-S | Brown | 4*4 |

1000/1500/2050/2700

3200/3600 |

460 | 360 | 360 | —— |

| WB04-S | Black | 4*4 |

1000/1500/2050/2700

3200/3600 |

460 | 360 | 360 | 10^7-10^5 | |

|

Kevlar

Double weft |

WG04-K | Glod | 4*4 |

1000/1500/2050/2700

3200/3600 |

420 | 680 | 460 | —— |