Update time: 2025-05-10 Views: 594

What Is Silicone-Coated Fiberglass Fabric?

Silicone-coated fiberglass fabric is a composite material made by bonding a layer of silicone rubber to a woven fiberglass substrate. Fiberglass, known for its high tensile strength and resistance to heat, chemicals, and moisture, serves as the robust foundation. The silicone coating adds critical properties such as:

Exceptional thermal stability (withstanding temperatures up to 500°C or higher, depending on formulation).

Non-stick surface for easy release of materials.

Flexibility even at extreme temperatures.

Chemical and corrosion resistance.

UV and weather resistance for outdoor durability.

This synergy creates a material that outperforms traditional fabrics in harsh environments.

Key Applications Across Industries

The versatility of silicone-coated fiberglass fabric makes it indispensable in multiple sectors:

Thermal Insulation & ProtectionUsed in welding blankets, fire curtains, and heat shields to protect personnel and equipment from high temperatures.

Ideal for exhaust systems, ductwork, and industrial ovens where heat dissipation and safety are critical.

Aerospace & AutomotiveEngine compartment liners, exhaust wraps, and thermal barriers in aircraft and vehicles benefit from its lightweight, heat-resistant properties.

Compliant with aviation and automotive safety standards.

Textile & Composite ManufacturingAs a release fabric for composites, it ensures smooth demolding of carbon fiber, fiberglass, or epoxy parts.

Used in conveyor belts for high-temperature drying and curing processes.

Construction & ArchitectureExpansion joint covers, gaskets, and fireproof membranes leverage its flexibility and fire resistance.

Ideal for curtain walls and roofing systems in fire-rated buildings.

Food Processing & PackagingNon-stick belts and mats for baking ovens, dryers, and conveyor systems.

FDA-compliant variants available for direct food contact.

Why Choose Silicone-Coated Fiberglass Fabric Over Alternatives?

Superior Heat Resistance: Unlike rubberized fabrics or PVC-coated materials, silicone remains stable at temperatures where others degrade.

Longevity: Resists abrasion, UV exposure, and chemical corrosion, reducing replacement costs.

Customizability: Available in various weights, thicknesses, and coatings (e.g., one-sided or two-sided) to suit specific needs.

Eco-Friendly: Silicone is inert and non-toxic, making it safer for workers and the environment.

How to Select the Right Silicone-Coated Fiberglass Fabric

When sourcing for your project, consider:

Temperature Rating: Ensure the fabric meets your application’s thermal requirements.

Thickness & Weight: Heavier fabrics offer more insulation but may sacrifice flexibility.

Coating Type: Double-sided silicone coatings provide better protection for applications requiring all-around durability.

Certifications: Look for industry-specific approvals (e.g., UL, NFPA, or military specs).

Partner with a Trusted Manufacturer

For businesses seeking reliable silicone-coated fiberglass fabric suppliers, partnering with a reputable manufacturer is key. Look for:

ISO-certified production facilities ensuring quality control.

Customization capabilities for bespoke solutions.

Global shipping and technical support to streamline your procurement process.

Conclusion: Invest in Quality, Reap Long-Term Benefits

Silicone-coated fiberglass fabric is more than just a material—it’s an investment in safety, efficiency, and durability. Whether you’re protecting workers in a foundry, enhancing manufacturing processes, or designing fire-resistant architecture, this composite fabric delivers results that last.

Previous: PTFE Film Adhesive Tape: The Ultimate High-Performance Solution for Industrial A...

Next: Innovative application and advantages of PTFE belt in food production line

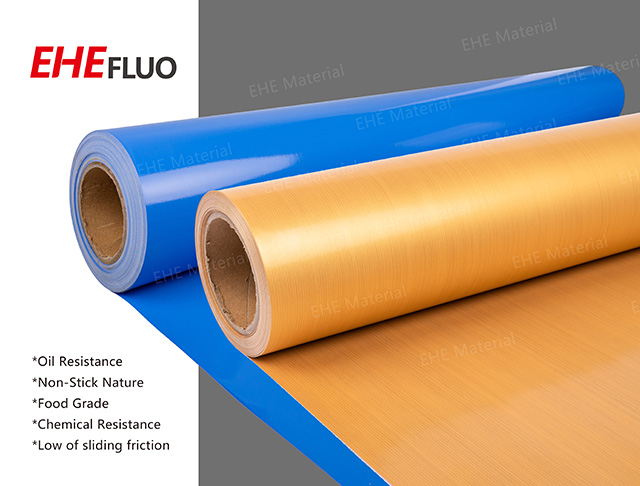

Oil resistant PTFE Fabric is used in a wide variety of industrial food processing applications, including contact belt grills, where high productivity is achieved by cooking between upper and lower heated belts. Laminated fabric is the product of choice whenever processing requires high heat and thr...

More Info

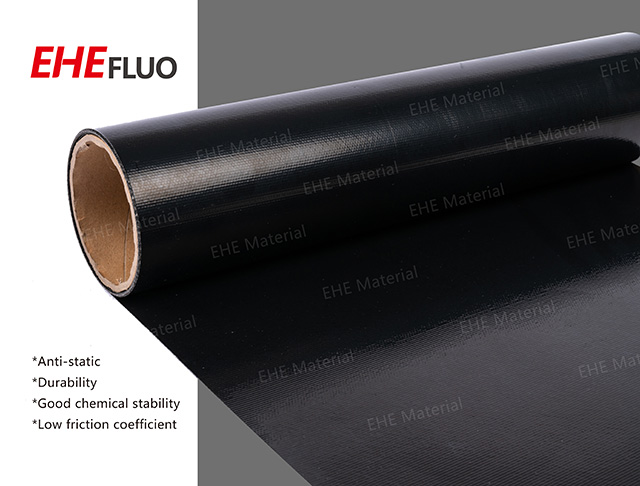

Anti-Static Black PTFE Fabric – The EB series is made by combining premium grade fiberglass fabric, PTFE and carbon or graphite to the coating process. These fabrics can be grounded to eliminate static electricity during operation.

More Info

PTFE glass fabric is a high-performance material created by impregnating woven fiberglass fabric with PTFE, resulting in a durable and versatile product. This combination endows the fabric with remarkable attributes, including heat resistance, low friction, excellent electrical properties, and resis...

More Info